Enhancing Food Safety and Quality in the UAE using Teledyne FLIR Thermal Imaging Cameras

Ti Thermal Imaging, an approved distributor in the Middle East, is a leading provider of automation solutions tailored to the unique needs of the food industry. With expertise in delivering cutting-edge technologies, Ti Thermal Imaging specializes in offering Teledyne FLIR thermal imaging cameras as a transformative solution for ensuring food safety and quality.

In this article, we will delve into the capabilities of Teledyne FLIR cameras and highlight how Ti Thermal Imaging can assist you in optimizing automation processes in the food industry. For any inquiries or to discuss your specific application, please contact our team for expert advice and recommendations.

Automating Temperature Control in the Food Industry:

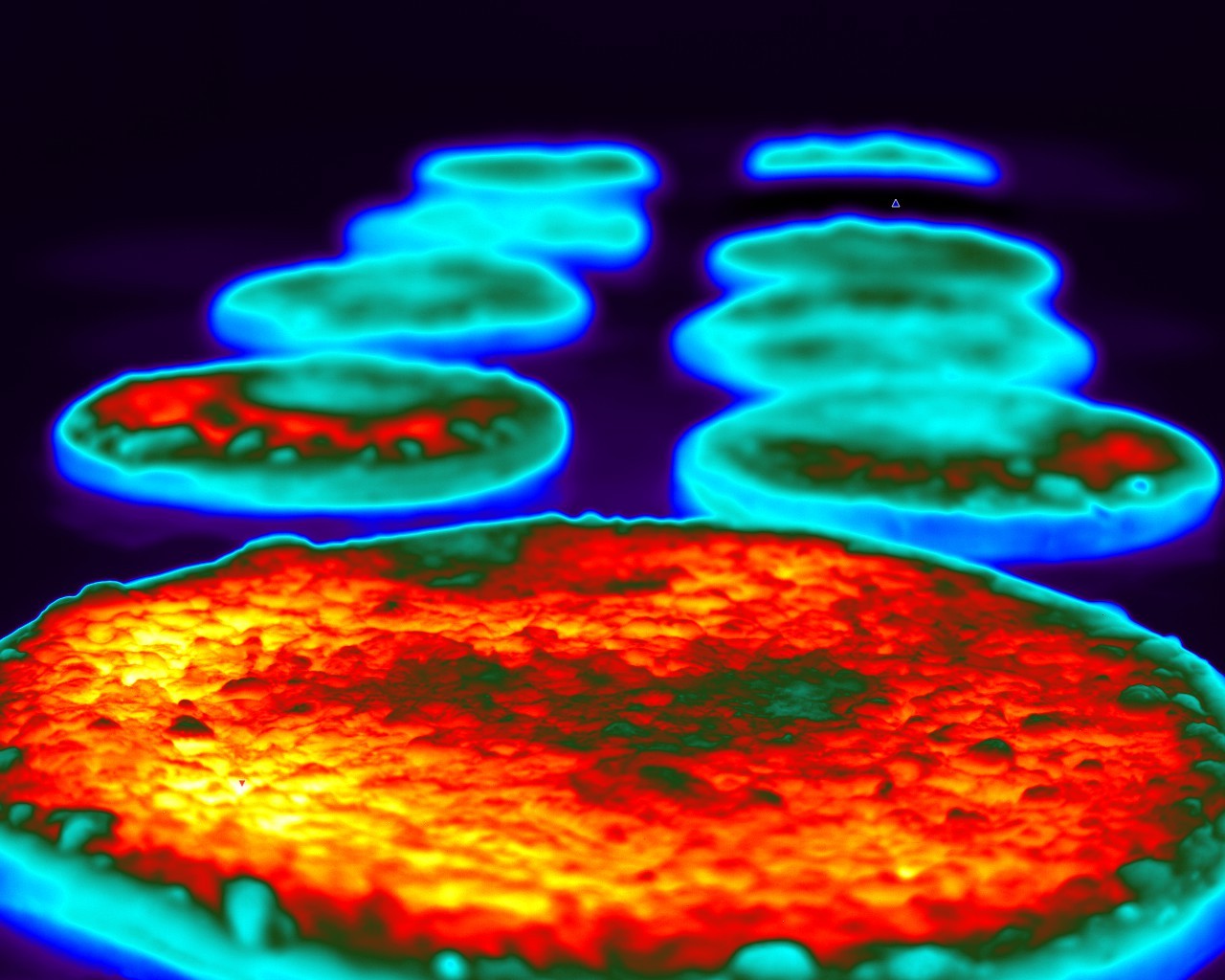

Thermal imaging cameras have emerged as invaluable tools in the food industry, enabling automated non-contact temperature measurements throughout various stages of food processing. Ti Thermal Imaging, in collaboration with Teledyne FLIR, offers state-of-the-art thermal imaging cameras that streamline operations, minimize human error, and reduce costs. These cameras are compact, user-friendly, and adaptable, allowing for flexible placement to meet the specific requirements of your application. With Ti Thermal Imaging’s expertise and Teledyne FLIR’s advanced technology, you can achieve precise temperature control and ensure the safety and quality of your perishable goods.

Applications in the Food Industry: Teledyne FLIR thermal imaging cameras, distributed by Ti Thermal Imaging, find extensive applications in the food industry, empowering businesses to enhance their processes and elevate their standards. Here are some key applications:

- Oven Baked Goods: Ti Thermal Imaging’s Teledyne FLIR cameras enable real-time monitoring of oven-baked goods, ensuring optimal cooking without over-drying or overcooking. By recording temperature profiles as products exit conveyor ovens, these cameras help maintain moisture content and improve overall yield.

- Microwave Cooking: With precise temperature measurements, Teledyne FLIR cameras enhance microwave cooking processes for meats, as well as the drying of parboiled rice and grains. By improving product quality and safety while reducing energy costs, these cameras provide significant advantages for the food industry.

- Packaging Inspections: Ti Thermal Imaging’s thermal imaging cameras, combined with pattern recognition software, facilitate automated inspections of frozen meal trays, verifying proper filling of food compartments. Additionally, these cameras detect heat radiating from container lips, ensuring the integrity of heat-sealed cellophane covers on finished microwave meals. The cameras can also analyze glue spots on overwrap cartons, minimizing quality control costs and enhancing product safety.

- Equipment Monitoring: Ti Thermal Imaging’s Teledyne FLIR cameras play a vital role in monitoring conveyor ovens, detecting temperature variations across the cooking belt’s width. By quickly identifying heating element failures or uneven heating, these cameras enable prompt corrective actions, reducing product variability and improving overall quality.

Ti Thermal Imaging Advantage for our clients:

As an approved distributor specializing in automation solutions for the food industry, Ti Thermal Imaging offers unique advantages to businesses seeking to optimize their processes with Teledyne FLIR thermal imaging cameras. Our expertise and commitment to customer satisfaction ensure that you receive tailored recommendations and support for your specific application requirements. Whether you need assistance in selecting the right camera model, integrating it into your existing automation systems, or troubleshooting any issues, our team of experts is here to